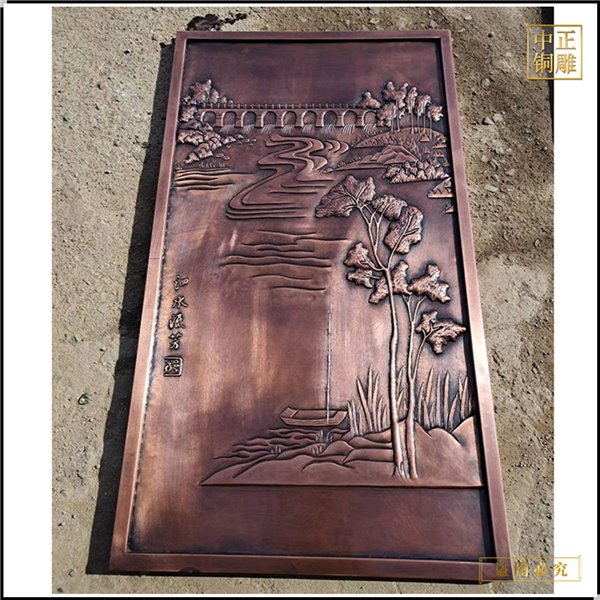

铜浮雕壁画是怎么被师傅们制作出来的

铜浮雕壁画在近些年来深受大家的喜爱,它具有自己独特的魅力,可不少人都在好奇,铜浮雕是怎么制作出来的,下面铜浮雕厂家就来简单的讲述一下浮雕的制作过程。

Copper relief murals have been deeply loved by everyone in recent years. It has its own unique charm, but many people are curious about how copper relief is made. Next, copper relief manufacturers will briefly talk about the production process of relief.

1、泥塑模型制造:依据设计方案进行平等尺度的泥塑制造,有时候需求制造小稿,然后再进行小稿放大制造。

1. Clay sculpture model manufacturing: clay sculpture manufacturing with equal scale is carried out according to the design scheme. Sometimes it is necessary to manufacture small drafts, and then enlarge the small drafts.

2、泥塑模型翻模:等泥塑模型制造完结并经客户确认无误后就可以翻模了,这儿一般是玻璃钢稿翻制。

2. Clay model turnover: after the clay model is manufactured and confirmed by the customer, the mold can be turned. Here, it is generally made of FRP.

3、下料和锻制:小型铜浮雕或大型铜浮雕局部加工可以采纳氧气加乙炔生产高温加热,大型铜浮雕就需求生炉火鼓风加热,等加热后用铁皮将铜板击打平坦。

3. Blanking and forging: local processing of small copper relief or large copper relief can adopt oxygen and acetylene to produce high-temperature heating. Large copper relief needs furnace fire and blast heating. After heating, hit the copper plate flat with iron sheet.

将适当份额的松香和土等原料放在容器内消融,再将其倒入四周有3—5厘米高出边沿的作业台,用于固定加热后的铜板。工艺师们在铜板上用錾手勾勒出凹凸起伏的线条。

Put an appropriate share of raw materials such as rosin and soil into the container for melting, and then pour them into the worktable with a height of 3-5cm above the edge to fix the heated copper plate. Craftsmen used chisels to outline the undulating lines on the copper plate.

4、拼装与上色:在锻造进行至必定阶段时,即可将锻制好的铜板依据玻璃钢稿依次焊接拼装拼装,然后就可以进行打磨刨光和上色处理,等上色完后需喷涂维护漆,等做完这些作业后,一件铜浮雕壁画作品就算完结了。

4. Assembly and coloring: when the forging reaches a certain stage, the forged copper plates can be welded and assembled in turn according to the FRP draft, and then they can be polished, planed and colored. After coloring, maintenance paint needs to be sprayed. After these operations, a copper relief work is finished.